A hydraulic system is a special type of system that causes large machines to move and do work, similar to how your muscles move your body. When you consider how to pick something heavy up or pull a door open, that’s your muscles doing their work. Likewise, hydraulic systems employ power to do critical work, moving machines. The power originates from hydraulic pumps. These types of pumps draw energy from their surroundings, such as electric motors or car engines. They employ this energy to pump fluid through pipelines. This liquid is very crucial because it moves various components of the machine, with motors, and other cogs used many tasks that make the machine run smoothly!

Hydraulic pumps are among the most hard-working pieces of a machine. They do so much and take on so much pressure every single day. When you need to take care of the muscles, change between exercise and rest, hydraulic pumps also require constant attention to ensure that these mechanical devices work properly. We have to keep checking them for any signs of wear and tear, which means that there are certain parts that are getting old or getting damaged. Replace any broken parts immediately if we find them. It is also really important to keep the pumps clean and well-oiled. This enables them to function properly and avoids any issues that might cause the machine to stop working.

Hydraulic pumps make wonderful and potentially even better devices when coupled with a gearbox to help them do their job. And a gearbox is kind of like a team of gears working together. These gears are similar to helping help with something moving from one end to another, like throwing a ball to a friend from game. In a gearbox hydraulic pump, a motor or engine rotates a group of gears to assist the hydraulic pump. 、 That means that it can do its job without having to strain, which is key to keeping the machine flowing properly.

We develop unique gearboxes for NanJing Fourall that operate flawlessly with various sorts of hydraulic pumps. And the way that a good pair of shoes can make you run faster, our gearboxes make it easier for hydraulic pumps to function. We opt for robust and high-grade materials to ensure that our gearboxes remain durable for many years ahead, even when working hard. We also focus on how we make them, utilizing precision manufacturing processes. By this means, our gearboxes cooperate optimally with other components of the hydraulic system, ensuring a smooth functionality of the complete device.

If you use a gearbox to make your hydraulic pump work better, you can see a big change in how your system is performing. The different gears in the gearbox serve to stabilize the pump, which cuts down on noise and makes everything function more efficiently. Just like a well-tuned bicycle rides better than a wobbly bicycle! The better the pump runs, the more work it can do using less power. This allows the machine to function correctly and prevents you from wasting time and money, both of which are positives.

We have supplied lubrication systems that has a capacity of 6000 MW, and more than hydraulic pump drive gearbox water cooling systems. We have also served more than 1, 000 wind farms as well as more than 300 wind turbine manufacturers. Have formed a win-win collaboration with several renowned domestic major component manufacturers, like CSSC, NGC, DHHI, etc. Just received a water cooling system for Dongfang Electric Wind Power Group’s offshore 10MW project in Danzhou. Accepted by March 2024 and delivered by April, 60 units will be assembled before July. Our advanced, patented performance of heat dissipation in our wind tunnel lab enabled this achievement. This achievement demonstrates Fourall's commitment to innovation and dedication to providing products and services that are of the highest quality while supporting global renewable energy developments.

Fourall team is an expert in fluid technology and the products that are widely utilized in photovoltaic power generation, hydraulic pump drive gearbox, metallurgy construction materials and the petrochemical industry. We develop customized lubrication solutions, cooling systems, hydraulic systems, components, and cylinders for large-scale equipment. We can provide professional technical assistance and services for various industries. We offer high standards of craftsmanship and quality management.Our technology is used successfully in Substation SVC Converter Cooling System. cooling system for SVG Converter in Substation. Lubricating oil stations and cooling systems for the metallurgical and petrochemical industries. Building Material Industry Lubrication system and hydraulic system that includes cooling system.

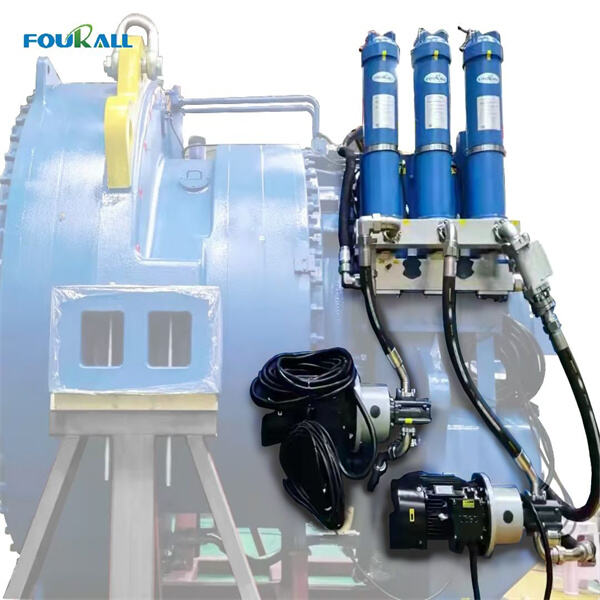

Fourall Company has classified products into two categories: hydraulic pump drive gearbox, water cooling, and hydraulic products for wind power applications. Water cooling systems designed for large-scale power and industrial applications. Wind power products are classified into five groups that each have more than 40 specifications. These include the wind power lubrication WD Series, water-cooled OS Series as well as the FA/HC filter element series and patented products like the pressure follow-up temperature controller FA/D series. We adhere to the SO9001/14001/18001 standard management system and other standards to provide a comprehensive information system and a vertical after-sales program. This includes RD Marketing, RD, Supply Chain, Manufacturing, Quality Management and we're able to react quickly to the demands of our customers. We can also offer fast and efficient service. The company's offices are located in Nanjing and Tianjin as well as a a team of professional sales, technology and support personnel to provide customers with quick as well as professional products and technical support.

Fourall team is hydraulic pump drive gearbox to research, development and production of components, fluids and products designed for use in the field of new energy large-scale power electronics. Our product line includes Lubrication systems; oil-cooling water-cooling and air cooling systems filters such as gear pumps; mechanical pumps; oil pipe; pressure-related TCV filtration; off-line bypass systems, and more.Fourall's highly-experienced RD team, with deep knowledge of industrial fluid applications and a decade or more of experience in wind energy fluid product application, can quickly determine and provide technological solutions. Fourall's high-tech processing technology, advanced testing equipment and quality assurance systems, as well as strict quality management methods are based on the most advanced testing and quality assurance systems.